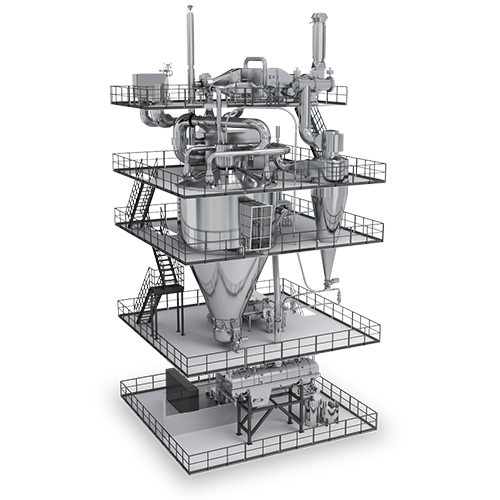

The spray dryer permits producing powders by means of water evaporation and applies to solutions, suspensions or emulsions. Once the operating parameters have been defined, this is a solution which permits obtaining powders or small agglomerates with defined and constant characteristics (humidity, grain size distribution, density). The process envisages the spray drying of the concentrated food liquid in small drops inside a chamber where hot air circulates.